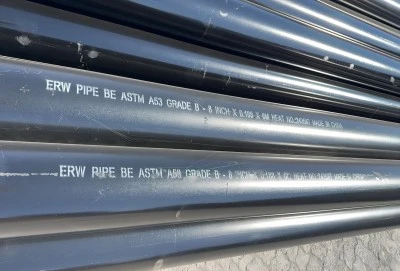

When it comes to piping systems, understanding the specifications of the materials used is crucial for ensuring safety, efficiency, and longevity. One of the most commonly used pipes in various industries is the astm a53 steel pipe, particularly the Grade B variant. In this comprehensive guide, we'll delve into the intricacies of ASTM A53 Grade B pipe thickness, exploring its range, calculation methods, and factors that influence thickness selection. We'll also examine real-world applications to give you a practical understanding of how these pipes are utilized in different scenarios.

|

|

|

Wall Thickness Range And Calculation Method

astm a53 steel pipe is available in a wide range of wall thicknesses to meet the demands of various applications and pressure requirements. These pipes typically range from 0.068 inches (1.73 mm) to 1.000 inches (25.4 mm) in wall thickness, depending on the nominal pipe size and schedule. The flexibility in wall thickness allows for customization based on the specific needs of different industries, such as oil and gas, construction, and chemical processing. Thicker-walled pipes are often used for higher-pressure applications, providing enhanced strength and durability, while thinner walls are suitable for lower-pressure systems.

To calculate the wall thickness of ASTM A53 Grade B pipes, engineers and designers use specific formulas that take into account factors such as internal pressure, temperature, and safety factors. The most common method for determining the minimum required wall thickness is the Barlow's formula:

t = (P * D) / (2 * S * E)

Where: t = minimum required wall thickness P = internal design pressure D = outside diameter of the pipe S = allowable stress value E = joint efficiency factor (usually 1.0 for seamless pipes)

It's important to note that the wall thickness values provided for ASTM A53 Grade B pipes represent the minimum required thickness according to the specifications. In practice, manufacturers often produce pipes with slightly thicker walls to account for manufacturing tolerances and ensure they meet or exceed industry standards. These extra allowances help to accommodate slight variations in the production process, ensuring the pipes maintain consistent strength and performance throughout their service life. By slightly over-sizing the wall thickness, manufacturers also provide an added margin of safety, making the pipes more reliable for demanding applications in high-pressure environments.

For example, a 4-inch Schedule 40 ASTM A53 Grade B pipe has a nominal wall thickness of 0.237 inches (6.02 mm). This thickness is suitable for many common applications, providing a balance between strength and weight.

Factors Influence Wall Thickness Selection

Selecting the appropriate wall thickness for astm a53 steel pipe is a critical decision that impacts the performance, safety, and cost-effectiveness of a piping system. Several factors come into play when determining the ideal thickness:

- Operating Pressure: Higher internal pressures require thicker pipe walls to withstand the stress. Engineers must consider both normal operating pressures and potential pressure surges.

- Temperature: Extreme temperatures can affect the strength of the steel. Higher temperatures may necessitate thicker walls to maintain structural integrity.

- Corrosion Allowance: In environments where corrosion is a concern, additional thickness may be added to extend the pipe's service life.

- External Loads: Pipes subjected to external forces, such as soil pressure in underground installations, may require thicker walls.

- Safety Factors: Industry standards and regulatory requirements often dictate minimum safety factors that influence wall thickness calculations.

- Cost Considerations: While thicker walls provide greater strength, they also increase material costs. Engineers must balance safety with economic feasibility.

- Installation Method: The chosen installation technique (e.g., welding, threading) may impact the required wall thickness.

By carefully considering these factors, engineers can select the optimal wall thickness for ASTM A53 Grade B pipes, ensuring reliable and efficient performance in diverse applications.

Actual Application Case Analysis

To better understand how astm a53 steel pipe thickness considerations play out in real-world scenarios, let's examine a few practical applications:

1. Industrial Process Piping: In a chemical processing plant, ASTM A53 Grade B pipes with a 6-inch nominal diameter and Schedule 80 wall thickness (0.432 inches or 10.97 mm) were selected for a high-pressure steam distribution system. The thicker walls were chosen to withstand the high temperatures and pressures associated with steam transport, as well as to provide an extra corrosion allowance in the aggressive industrial environment.

2. Natural Gas Distribution: A municipal natural gas distribution network utilized 2-inch Schedule 40 ASTM A53 Grade B pipes with a wall thickness of 0.154 inches (3.91 mm). This thickness was deemed sufficient for the moderate pressures involved in residential gas distribution while also providing a good balance between material cost and durability for underground installation.

3. Structural Applications: In the construction of a multi-story parking garage, 4-inch Schedule 40 ASTM A53 Grade B pipes with a wall thickness of 0.237 inches (6.02 mm) were used as structural supports. The thickness was selected to provide adequate load-bearing capacity while keeping the overall weight of the structure manageable.

4. Fire Protection Systems: A high-rise office building's fire sprinkler system employed 3-inch Schedule 10 ASTM A53 Grade B pipes with a wall thickness of 0.120 inches (3.05 mm). This lighter-weight option was chosen because fire protection systems typically operate at lower pressures, and the thinner walls facilitated easier installation in tight spaces.

These examples illustrate how the selection of ASTM A53 Steel Pipe thickness is tailored to the specific requirements of each application, balancing factors such as pressure ratings, environmental conditions, and cost considerations.

Longma Group ASTM A53 Steel Pipe

Understanding the intricacies of astm a53 steel pipe thickness is crucial for engineers, contractors, and project managers involved in piping system design and installation. By considering factors such as operating pressure, temperature, and environmental conditions, professionals can select the optimal wall thickness to ensure safety, efficiency, and longevity in their piping systems.

Longma Group offers customization options for ASTM A53 ERW Pipe to meet the unique specifications and dimensions of individual projects, ensuring precise fit and functionality. If you are choosing your wholesale astm a53 erw steel pipe factories, welcome to contact LONGMA GROUP at info@longma-group.com.