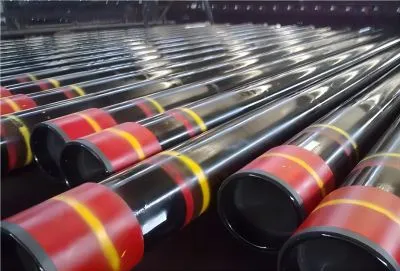

Oil Country Tubular Goods (OCTG) play a crucial role in the oil and gas industry, serving as the backbone of drilling and production operations. The choice of materials used in OCTG pipe manufacturing is of paramount importance, as these pipes must withstand extreme conditions, including high pressures, corrosive environments, and varying temperatures. In this comprehensive guide, we'll explore the materials used in OCTG tubing production, the commonly used steel grades, and how their composition affects performance.

|

|

|

What are the Commonly Used Steel Grades in OCTG Manufacturing?

OCTG pipes are primarily manufactured using various grades of steel, each designed to meet specific performance requirements. The choice of steel grade depends on factors such as the well depth, pressure conditions, and corrosive elements present in the drilling environment. Some of the most commonly used steel grades in OCTG manufacturing include:

- API 5CT Grade J55: This is a standard grade used for general purpose casing and tubing applications. It offers good strength and ductility, making it suitable for moderate depth wells with relatively low pressure and temperature conditions.

- API 5CT Grade N80: Known for its higher yield strength compared to J55, N80 is widely used in deeper wells and more demanding environments. It provides improved resistance to collapse and burst pressures.

- API 5CT Grade P110: This high-strength grade is designed for use in deep wells with high pressure and temperature conditions. It offers excellent resistance to collapse, burst, and tension loads.

- API 5CT Grade Q125: One of the highest strength grades available, Q125 is used in extremely demanding applications where exceptional mechanical properties are required.

- API 5CT Grade L80: This grade is specifically designed for use in sour service environments, offering improved resistance to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC).

These grades are just a few examples of the wide range of steel grades used in OCTG manufacturing. The selection of the appropriate grade depends on the specific requirements of each well and the operating conditions it will face.

How Does Carbon Content Influence OCTG Pipe Performance?

Carbon content plays a crucial role in determining the mechanical properties and performance characteristics of OCTG pipes. The amount of carbon in the steel composition significantly influences factors such as strength, hardness, and weldability. Let's explore how carbon content affects various aspects of pipe performance:

- Strength and Hardness: Generally, as the carbon content increases, the strength and hardness of the steel also increase. This is because carbon forms carbides with iron, which strengthens the steel's microstructure. Higher carbon content can lead to improved yield strength and tensile strength, making the pipe more resistant to deformation under load.

- Toughness: While increasing carbon content enhances strength, it can also reduce the steel's toughness. Toughness is the ability of the material to absorb energy before fracturing. OCTG pipes need to balance strength with toughness to withstand the dynamic loads and potential impacts during drilling and production operations.

- Weldability: Carbon content significantly affects the weldability of steel. As carbon content increases, the steel becomes more difficult to weld without introducing defects or altering the material's properties in the heat-affected zone. This is particularly important for OCTG applications where field welding may be required.

- Corrosion Resistance: While carbon content itself doesn't directly improve corrosion resistance, it influences the overall alloy composition and heat treatment processes that can enhance the steel's ability to withstand corrosive environments.

- Formability: Lower carbon content generally improves the formability of steel, which can be advantageous during the manufacturing process of OCTG pipes, especially for seamless pipe production.

The optimal carbon content for OCTG pipes varies depending on the specific grade and intended application. For example, API 5CT Grade J55 typically has a carbon content of around 0.40% or less, while higher strength grades like P110 may have slightly higher carbon contents to achieve the required mechanical properties.

Why are High-Strength Low-Alloy Steels Preferred for OCTG Applications?

High-Strength Low-Alloy (HSLA) steels have gained significant popularity in OCTG applications due to their unique combination of properties that make them particularly well-suited for the demanding conditions encountered in oil and gas wells. Here are several reasons why HSLA steels are preferred for OCTG applications:

- Excellent Strength-to-Weight Ratio: HSLA steels offer high strength levels while maintaining relatively low overall alloy content. This results in pipes that are strong enough to withstand high pressures and loads but are not excessively heavy, making them easier to transport and handle during installation.

- Improved Weldability: Compared to higher carbon steels with similar strength levels, HSLA steels generally exhibit better weldability. This is crucial for OCTG applications where field welding may be necessary, ensuring the integrity of connections and reducing the risk of weld-related failures.

- Enhanced Toughness: HSLA steels are designed to provide a good balance between strength and toughness. This is essential for OCTG pipes that may be subjected to impact loads, cyclic stresses, and varying temperature conditions during their service life.

- Corrosion Resistance: Many HSLA steels used in OCTG applications are formulated with small additions of alloying elements that can improve corrosion resistance. This is particularly important in environments where H2S, CO2, or other corrosive agents are present.

- Cost-Effectiveness: While HSLA steels may be more expensive than basic carbon steels, they often prove more cost-effective in the long run due to their superior performance and longer service life in demanding OCTG applications.

- Versatility: HSLA steels can be tailored to meet specific property requirements by adjusting the alloy composition and heat treatment processes. This allows manufacturers to create OCTG pipes optimized for particular well conditions or regulatory standards.

- Improved Formability: Many HSLA steels offer good formability characteristics, which is advantageous during the manufacturing process, especially for seamless OCTG tubing production.

The use of HSLA steels in OCTG applications has contributed significantly to the industry's ability to drill deeper wells, operate in more challenging environments, and improve overall well performance and safety. As exploration and production activities continue to push into more extreme conditions, the role of advanced materials like HSLA steels in OCTG manufacturing is likely to become even more critical.

About Longma Group

The selection of materials for OCTG tubing manufacturing is a complex process that requires careful consideration of various factors, including well depth, pressure conditions, temperature, and corrosive environments. Steel grades ranging from standard API 5CT J55 to high-strength grades like P110 and Q125 are commonly used, each offering specific advantages for different applications.

The carbon content in these steels plays a crucial role in determining their mechanical properties, influencing factors such as strength, hardness, and weldability. Balancing these properties is essential for optimal OCTG pipe performance. The growing preference for High-Strength Low-Alloy (HSLA) steels in OCTG applications demonstrates the industry's focus on materials that offer an excellent combination of strength, toughness, and corrosion resistance while maintaining good weldability and formability.

As the oil and gas industry continues to evolve, with exploration and production activities venturing into more challenging environments, the importance of advanced materials in OCTG manufacturing cannot be overstated. The ongoing research and development in steel metallurgy and OCTG design will undoubtedly lead to even more innovative solutions, pushing the boundaries of what's possible in oil and gas extraction.

For those seeking high-quality OCTG tubing solutions, the Longma Group stands out as a leading manufacturer. With expertise in producing a wide range of OCTG products, including ERW and LSAW steel pipes, Longma Group offers solutions that meet the stringent requirements of the oil and gas industry. Their products adhere to international standards such as API 5L and API 5CT, with outer diameters ranging from 4" to 80" and thicknesses from SCH10 to SCH160. For more information or to discuss your specific OCTG tubing needs, please contact Longma Group at info@longma-group.com.