The major difference between black steel pipe and ERW steel pipe lies in their manufacturing processes and resulting properties. ERW black pipe, also known as Electric Resistance Welded pipe, is created by rolling flat steel into a tubular shape and welding the seam using electric current. In contrast, black steel pipe is typically seamless, manufactured through a hot-rolling process without welding. This fundamental difference impacts their strength, durability, and suitability for various applications in industries such as oil and gas, water supply, and construction.

|

|

|

Production Methods: Black Steel vs. ERW Techniques

Hot-rolled vs. Electric Resistance Welding Process

The production methods for black steel and ERW pipes differ significantly, influencing their final characteristics. Black steel pipes are manufactured using a hot-rolling process, where heated steel billets are pierced and formed into seamless tubes. This method creates a uniform structure throughout the pipe wall, enhancing its overall strength and pressure resistance.

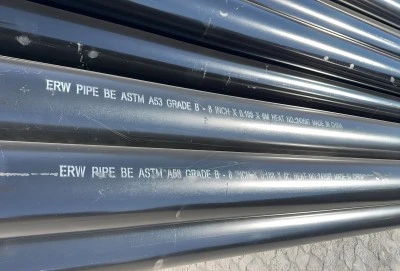

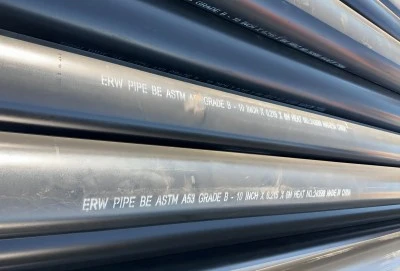

On the other hand, ERW black pipes are made by cold-forming steel sheets or strips into a cylindrical shape. The edges are then brought together and welded using high-frequency electric current, creating a distinctive longitudinal seam. This process allows for precise control over the pipe's dimensions and wall thickness, making ERW pipes ideal for applications requiring consistent sizing.

Seamless Nature of Black Steel Pipe Manufacturing

The seamless nature of black steel pipes is a key advantage in certain high-pressure applications. Without a welded seam, these pipes have uniform strength distribution across their entire surface, reducing potential weak points. This characteristic makes them particularly suitable for handling extreme pressures and temperatures in oil and gas transportation systems.

The seamless manufacturing process also contributes to black steel pipes' excellent roundness and straightness, crucial factors in long-distance fluid transportation. These properties minimize turbulence and pressure drops, ensuring efficient flow in pipelines.

ERW Pipe's Precision Welding Technology Advantages

While ERW black pipes have a welded seam, advancements in welding technology have significantly improved their performance. Modern ERW processes use high-frequency induction welding, which creates a strong, uniform seam that's often indistinguishable from the rest of the pipe wall in terms of strength.

This precision welding allows for greater control over the pipe's dimensions, resulting in tighter tolerances and more consistent wall thicknesses. Such accuracy is particularly beneficial in applications where exact fitting and joining are critical, such as in structural support or water distribution systems.

Application Areas

Black Steel in High-Pressure Oil and Gas PipelinesBlack steel pipes shine in high-pressure, high-temperature environments typical of oil and gas transportation. Their seamless construction provides superior resistance to internal pressures, making them the go-to choice for offshore platforms and long-distance pipelines. The absence of a weld seam eliminates a potential point of failure under extreme conditions, enhancing overall system reliability.

In the Middle East's vast oil fields, black steel pipes are extensively used for their ability to withstand the region's harsh desert conditions while maintaining structural integrity. Similarly, in Australia's MOBIL OIL projects, these pipes play a crucial role in transporting crude oil from extraction sites to refineries, demonstrating their suitability for large-scale industrial applications.

ERW Pipes in Water Supply and Structural Applications

ERW black pipes find their niche in water supply systems and structural applications. Their consistent dimensions and smooth internal surfaces make them ideal for efficient water distribution networks. In Southeast Asian countries, where rapid urbanization demands extensive water infrastructure, ERW pipes are widely used for their cost-effectiveness and ease of installation.

The construction industry also favors ERW pipes for structural support in buildings and bridges. Their precise sizing allows for easier integration into complex designs, while their strength-to-weight ratio makes them an economical choice for large-scale projects.

Comparing Strength in Bridge and Building Construction

When it comes to bridge and building construction, both black steel and ERW pipes have their merits. Black steel pipes, with their seamless structure, offer superior load-bearing capacity, making them suitable for critical support structures in high-rise buildings and long-span bridges.

ERW black pipes, while not as strong as seamless pipes under extreme loads, provide excellent performance in most standard construction applications. Their uniform wall thickness and precise dimensions make them easier to work with in complex architectural designs. In Australia's booming construction sector, ERW pipes are frequently used in commercial and residential buildings for their balance of strength, cost-effectiveness, and ease of fabrication.

Corrosion Resistance: Comparing Black Steel and ERW Pipes

Black Steel's Natural Oxide Layer ProtectionBlack steel pipes derive their name from the dark oxide layer that forms on their surface during the manufacturing process. This layer provides a degree of natural corrosion resistance, particularly useful in indoor applications or environments with low moisture levels. The oxide coating acts as a barrier, slowing down the corrosion process and extending the pipe's service life.

In industrial settings where aesthetics are secondary to functionality, the dark appearance of black steel pipes can be advantageous. It reduces light reflection, which can be beneficial in certain manufacturing environments. However, in highly corrosive environments like offshore platforms, additional protective measures are often necessary to ensure longevity.

ERW Pipe's Enhanced Corrosion-Resistant Coatings

ERW pipes often come with advanced corrosion-resistant coatings applied during or after the manufacturing process. These coatings can include galvanization, epoxy lining, or other specialized treatments designed to protect the pipe from both internal and external corrosion. This enhanced protection makes ERW pipes particularly suitable for water supply systems, where preventing rust and maintaining water quality is crucial.

In Southeast Asian countries with high humidity levels, coated ERW pipes are preferred for their ability to withstand moisture-rich environments. The coatings not only protect against corrosion but also can improve flow characteristics, reducing friction and enhancing overall system efficiency.

Long-term Durability in Harsh Environmental Conditions

When it comes to long-term durability in harsh conditions, both pipe types have their strengths. Black steel pipes, especially those with additional protective treatments, excel in high-temperature, high-pressure environments typical of oil and gas applications. Their seamless construction minimizes weak points that could be vulnerable to corrosion over time.

ERW pipes, with their advanced coatings, often outperform in environments with varied chemical exposures, such as industrial processing plants. In the Australian mining sector, where pipes are exposed to abrasive materials and corrosive chemicals, properly coated ERW pipes have demonstrated excellent longevity.

The choice between black steel and ERW pipes depends on the specific requirements of each project. Black steel pipes excel in high-pressure, high-temperature applications, making them ideal for oil and gas transportation. ERW pipes, with their precision manufacturing and versatile coating options, are well-suited for water supply systems and structural applications. Both types have their place in modern engineering, and understanding their differences is crucial for making informed decisions in pipeline and structural projects across the globe.

Where to Buy ERW and Black Steel Pipes?

For top-quality ERW black pipe and other steel piping solutions, look no further than Hebei Longma Group. Our advanced production equipment, imported from Germany, ensures precision manufacturing of steel pipes to meet diverse industry needs. With a professional team of over 300 employees, including 60+ technical experts, we guarantee superior product quality and innovative solutions.

Our comprehensive testing facilities, including ultrasonic flaw detectors and X-ray equipment, ensure every pipe meets stringent quality standards. We pride ourselves on fast delivery. Hebei Longma Group holds all necessary certifications, including API 5L, ISO 9001, and ISO 14001, assuring you of our commitment to quality and environmental responsibility.

Thanks to our strategic partnerships with raw material suppliers and efficient production processes, we offer competitive pricing without compromising on quality. For all your ERW and black steel pipe needs, contact us at info@longma-group.com.