When it comes to selecting pipes for various industrial applications, corrosion resistance is a critical factor. Among the top contenders, anti-corrosion steel pipes stand out as one of the most reliable options. These pipes, engineered with advanced materials and coating technologies, offer superior protection against environmental degradation. While several materials demonstrate corrosion-resistant properties, the choice often depends on specific project requirements, environmental conditions, and long-term cost considerations.

|

|

|

Top 3 Corrosion-Resistant Pipe Materials

Stainless Steel: The Industry Standard for Anti-Corrosion

Stainless steel has long been the go-to material for corrosion-resistant piping across various industries. Its inherent resistance to rust and corrosion makes it an excellent choice for applications in harsh environments. The addition of chromium to the steel creates a protective oxide layer, which self-heals when damaged, providing continuous protection against corrosive elements.

Different grades of stainless steel offer varying levels of corrosion resistance. For instance, austenitic stainless steels like 304 and 316 are widely used in chemical processing and marine applications due to their exceptional resistance to chloride-induced corrosion. These grades contain higher levels of nickel and molybdenum, enhancing their ability to withstand aggressive environments.

LSAW Pipes: Longma Group's Specialty for Durability

Longitudinal Submerged Arc Welded (LSAW) pipes have gained prominence in recent years, particularly in the oil and gas industry. These pipes, a specialty of Hebei Longma Group, offer superior strength and corrosion resistance compared to traditional welded pipes. The LSAW manufacturing process ensures a uniform weld seam, reducing weak points where corrosion might initiate.

LSAW pipes are often coated with advanced materials like fusion-bonded epoxy or polyethylene, further enhancing their corrosion resistance. This combination of high-quality steel and protective coatings makes LSAW pipes ideal for offshore pipelines and other demanding applications where corrosion resistance is paramount.

PVC and CPVC: Cost-Effective Alternatives for Corrosion Resistance

While not as robust as steel in terms of strength, Polyvinyl Chloride (PVC) and Chlorinated Polyvinyl Chloride (CPVC) pipes offer excellent corrosion resistance at a lower cost. These materials are impervious to most acids, bases, and salts, making them suitable for chemical processing and water treatment facilities.

CPVC, in particular, can withstand higher temperatures than standard PVC, expanding its range of applications. However, it's important to note that while these materials excel in corrosion resistance, they may not be suitable for high-pressure or high-temperature environments where steel pipes would be the preferred choice.

Factors Affecting Pipe Corrosion Resistance

Environmental Conditions: pH Levels and Chemical ExposureThe corrosion resistance of pipes is heavily influenced by the environment in which they operate. pH levels play a crucial role in determining the rate of corrosion. Highly acidic or alkaline environments can accelerate the corrosion process, even in materials typically considered corrosion-resistant.

Chemical exposure is another critical factor. For instance, chlorides are particularly aggressive towards many metals, including some grades of stainless steel. In offshore applications, where pipes are exposed to seawater rich in chlorides, special consideration must be given to material selection and protective measures.

Manufacturing Process: ERW vs LSAW Pipe Production

The manufacturing process of pipes significantly impacts their corrosion resistance. Electric Resistance Welded (ERW) pipes, while cost-effective, may have inconsistencies in the weld seam that can become initiation points for corrosion. In contrast, LSAW pipes offer a more uniform structure and typically higher corrosion resistance.

The LSAW process allows for better control over the pipe's microstructure and properties. This results in a more homogeneous material with fewer weak points susceptible to corrosion. For applications requiring the highest levels of corrosion resistance, LSAW pipes often prove to be the superior choice.

Coating Technologies: Enhancing Steel Pipe Corrosion Resistance

Coating technologies play a vital role in enhancing the corrosion resistance of steel pipes. Fusion-bonded epoxy (FBE) coatings are widely used in the oil and gas industry due to their excellent adhesion and chemical resistance. These coatings form a barrier between the steel and corrosive elements, significantly extending the pipe's service life.

Other coating options include polyethylene and polypropylene, which offer excellent resistance to soil-based corrosion in buried pipelines. For offshore applications, multi-layer coating systems combining FBE with polyolefin layers provide enhanced protection against mechanical damage and permeation.

Cost vs. Durability: Choosing the Right Pipe

Lifecycle Cost Analysis of Anti-Corrosion Steel PipesWhen evaluating the cost-effectiveness of anti-corrosion steel pipes, it's crucial to consider the total lifecycle cost rather than just the initial investment. While corrosion-resistant materials and coatings may increase upfront costs, they often result in significant long-term savings through reduced maintenance and replacement needs.

For instance, a properly specified and installed anti-corrosion steel pipe system can offer a service life of 50 years or more in many applications. This longevity must be weighed against the costs of potential downtime, repairs, and replacements associated with less durable alternatives. In industries where pipeline failures can lead to catastrophic environmental or economic consequences, the value of reliable corrosion resistance becomes even more apparent.

Industry-Specific Pipe Selection: Oil & Gas vs Water Supply

Different industries have unique requirements when it comes to pipe selection. In the oil and gas sector, pipes must withstand not only corrosive fluids but also high pressures and temperatures. Here, high-grade stainless steel or coated carbon steel pipes are often the preferred choice, with LSAW pipes gaining popularity for their superior performance.

In contrast, water supply systems may prioritize cost-effectiveness and long-term stability. While stainless steel remains an excellent choice for critical components, ductile iron or PVC pipes with appropriate coatings can provide adequate corrosion resistance for many municipal water applications. The key is to balance corrosion resistance with other factors such as pressure ratings, ease of installation, and local regulatory requirements.

Global Market Trends: Middle East and Southeast Asia Demand

The demand for corrosion-resistant pipes is particularly strong in regions with challenging environmental conditions. In the Middle East, where high temperatures and saline soils accelerate corrosion, there's a growing preference for high-performance anti-corrosion steel pipes. Projects like desalination plants and oil refineries in this region often specify advanced corrosion-resistant materials to ensure long-term reliability.

Southeast Asia, with its tropical climate and rapidly expanding infrastructure, presents another hotspot for corrosion-resistant pipe demand. As countries in this region invest in upgrading their water supply systems and expanding their industrial capabilities, the need for durable, corrosion-resistant piping solutions continues to grow. This trend is driving innovation in coating technologies and material science, pushing the boundaries of what's possible in corrosion resistance.

Selecting the most corrosion-resistant pipe involves careful consideration of material properties, environmental conditions, and long-term cost-effectiveness. While stainless steel remains a top choice for many applications, innovative solutions like LSAW pipes and advanced coating technologies are expanding the options available to engineers and project managers. By understanding the factors affecting corrosion resistance and staying informed about market trends, industries can make informed decisions to ensure the longevity and reliability of their piping systems. As global demand for infrastructure development continues to grow, the importance of corrosion-resistant piping solutions will only increase, driving further advancements in this critical field.

Anti-Corrosion Steel Pipe For Sale

Hebei Longma Group stands at the forefront of steel pipe manufacturing, offering cutting-edge solutions for demanding industrial applications. Our state-of-the-art production facilities, equipped with German-imported machinery and four proprietary production lines, ensure unparalleled quality and precision. With a team of over 300 skilled professionals, including 60+ technical experts and an independent research unit, we drive innovation in corrosion-resistant pipe technology.

Our comprehensive testing facilities, featuring online ultrasonic flaw detectors and industrial X-ray systems, guarantee the highest standards of product integrity. We pride ourselves on rapid delivery, with standard thickness pipes ready in as little as 7 days. Backed by a full range of international certifications, including API 5L and ISO 9001, our products meet the most stringent industry requirements.

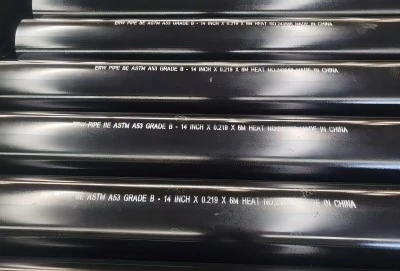

Thanks to our established relationships with raw material suppliers and an integrated production model, we offer competitive pricing without compromising on quality. Our anti-corrosion steel pipes, available in diameters from 60.3mm to 1422mm and wall thicknesses of 6.02mm to 50.8mm, meet API 5L, ASTM A53, EN10210, and AS/NZS 1163 standards. Various coating options, compliant with international standards like DIN 30670 and ISO21809-1, ensure optimal protection against corrosion in diverse environments.

For inquiries about our premium steel pipes or to discuss your project requirements, contact us at info@longma-group.com. Our team of experts is ready to provide tailored solutions for your corrosion resistance needs, ensuring the longevity and reliability of your piping systems.