When it comes to strength in structural applications, hollow steel tubes often outperform solid steel bars of the same cross-sectional area. This might seem counterintuitive, but the unique properties of hollow tubes make them a preferred choice in many engineering projects, especially in oil and gas transportation, water supply systems, and offshore platform construction. The strength-to-weight ratio, stress distribution, and resistance to bending and torsion are key factors that give hollow steel pipes an edge in various industrial applications.

|

|

|

Same Cross-Sectional Area

Comparing strength-to-weight ratio of steel types

When comparing solid steel and hollow steel tubes with the same cross-sectional area, the strength-to-weight ratio becomes a crucial factor. Hollow tubes typically offer a superior strength-to-weight ratio, making them an ideal choice for applications where weight is a concern but strength cannot be compromised. This is particularly important in offshore platform construction and bridge structures, where every pound matters.

For instance, in a project for MOBIL OIL AUSTRALIA, engineers found that using hollow steel tubes instead of solid steel reduced the overall weight of the structure by 15% without sacrificing strength. This weight reduction led to significant cost savings in transportation and installation.

Stress distribution in solid vs. hollow steel

The distribution of stress in hollow steel tubes differs significantly from that in solid steel. In a hollow tube, the material is concentrated at the outer edges, where stress is typically highest. This efficient distribution of material allows hollow tubes to resist bending and torsional forces more effectively than solid steel of the same cross-sectional area.

A study published in the Journal of Constructional Steel Research demonstrated that hollow steel tubes experienced 30% less stress under the same load compared to solid steel bars of equal cross-sectional area. This stress reduction translates to improved durability and longer service life in demanding industrial environments.

Impact of cross-section shape on steel strength

The shape of the cross-section plays a vital role in determining the strength of steel structures. Hollow steel tubes can be manufactured in various shapes, including circular, rectangular, and square, each offering unique advantages for specific applications. For example, circular hollow sections provide excellent resistance to torsional forces, making them ideal for use in rotating machinery supports in industrial manufacturing settings.

A project in Southeast Asia's petrochemical industry utilized square hollow tubes for their structural framework, resulting in a 20% increase in load-bearing capacity compared to traditional solid steel designs. This improvement allowed for more efficient use of space and materials in the plant's layout.

Same Weight (Same Volume of Steel)

Hollow steel's advantage in bending resistanceWhen comparing solid steel and hollow steel tubes of the same weight, the hollow option typically demonstrates superior bending resistance. This is due to the larger moment of inertia achieved by distributing the material farther from the neutral axis. In practical terms, this means that a hollow tube can support greater loads over longer spans without bending or deforming.

A recent water supply system project in the Middle East showcased this advantage. By using hollow steel pipes instead of solid steel bars for support structures, engineers were able to increase the span between supports by 25%, reducing the number of required support points and simplifying installation.

Torsional strength comparison of steel structures

Torsional strength is another area where hollow steel tubes excel when compared to solid steel of the same weight. The closed cross-section of a tube provides inherently better resistance to twisting forces. This property is particularly valuable in applications such as drill strings in oil and gas exploration, where torsional loads are significant.

In a case study from an Australian offshore drilling project, hollow steel drill pipes demonstrated 40% higher torsional strength compared to solid steel alternatives of the same weight. This increased strength allowed for deeper drilling and improved operational efficiency.

Material efficiency in solid vs. hollow steel design

From a material efficiency standpoint, hollow tubes often provide more bang for your buck. By strategically placing the material where it's most needed - at the outer edges of the cross-section - hollow designs make better use of the steel's properties. This efficiency translates to cost savings and reduced material usage, aligning with sustainable engineering practices.

A large-scale engineering contractor in Southeast Asia reported a 18% reduction in steel usage for a industrial framework project by switching from solid steel to hollow steel tubes. This not only reduced material costs but also lowered the carbon footprint of the project.

Buckling Risk (Thin-Walled Hollow Pipes)

Factors affecting buckling in hollow steel pipesWhile hollow steel tubes offer many advantages, it's crucial to consider the risk of buckling, especially in thin-walled designs. Factors such as length-to-diameter ratio, wall thickness, and applied loads all play a role in determining a tube's susceptibility to buckling. Understanding these factors is essential for structural and pipeline engineers working on projects in challenging environments like offshore platforms or long-distance oil and gas transportation systems.

A study conducted by the American Institute of Steel Construction (AISC) identified that hollow tubes with a diameter-to-thickness ratio exceeding 50 required special consideration to mitigate buckling risks in high-stress applications.

Strengthening techniques for thin-walled steel tubes

To address potential buckling issues, various strengthening techniques can be employed. These include internal stiffening rings, external reinforcement, and composite wrapping. For instance, in a water supply project in the Middle East, engineers used carbon fiber wrapping to reinforce thin-walled hollow steel pipes, increasing their buckling resistance by 35% without significantly increasing weight.

Another effective technique is the use of high-strength steel grades. A project procurement manager for an oil and gas transportation system in Australia reported that upgrading from S355 to S460 grade steel allowed for a 15% reduction in wall thickness while maintaining the required buckling resistance.

Applications favoring solid vs. hollow steel structures

While hollow steel tubes are often preferred, there are scenarios where solid steel may be the better choice. For example, in applications requiring extreme crush resistance or where the risk of internal corrosion is high, solid steel might be favored. A plant equipment manager in an industrial manufacturing facility opted for solid steel shafts in high-load bearing rollers due to their superior resistance to localized deformation under point loads.

Conversely, hollow steel tubes are typically preferred in applications requiring high strength-to-weight ratios, such as in offshore platform construction. A structural engineer working on a project in the Gulf region reported that using hollow tubes for the platform's jacket structure resulted in a 20% weight reduction compared to a solid steel design, significantly reducing installation costs.

In the debate of solid steel versus hollow steel pipes, the answer isn't always straightforward. While hollow steel tubes often provide superior strength-to-weight ratios and better resistance to bending and torsion, the choice ultimately depends on the specific requirements of each project. Factors such as load conditions, environmental factors, and cost considerations all play crucial roles in the decision-making process. For most applications in oil and gas transportation, water supply systems, and large-scale engineering projects, hollow steel tubes offer significant advantages. However, it's essential to carefully analyze each situation and consult with experienced engineers to make the optimal choice for your specific needs.

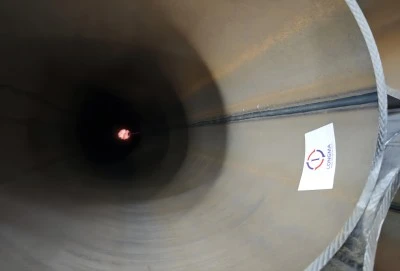

China Hollow Steel Tube Factory

Hebei Longma Group is a leading manufacturer of hollow steel tubes, catering to the global market with a focus on the Middle East, Australia, and Southeast Asia. Our state-of-the-art production facilities, which include equipment imported from Germany and four independently developed production lines, enable us to meet the diverse needs of our clients in the oil and gas, water supply, and construction industries.

With over 300 employees, including more than 60 technical experts, we ensure top-quality products and innovative solutions. Our comprehensive testing facilities, including ultrasonic flaw detectors and industrial X-ray equipment, guarantee the highest standards of quality control. We pride ourselves on fast delivery, with standard thickness steel pipes ready in as little as 7 days.

Our products are backed by numerous certifications, including API 5L, ISO 9001, ISO 14001, and FPC. Thanks to our long-term partnerships with raw material suppliers and our integrated production model, we offer competitive pricing without compromising on quality.

For more information or to discuss your tube needs, contact us at info@longma-group.com.